Carbon Neutral Farming

Straus Dairy Farm's Carbon Neutral Goal Draws Near

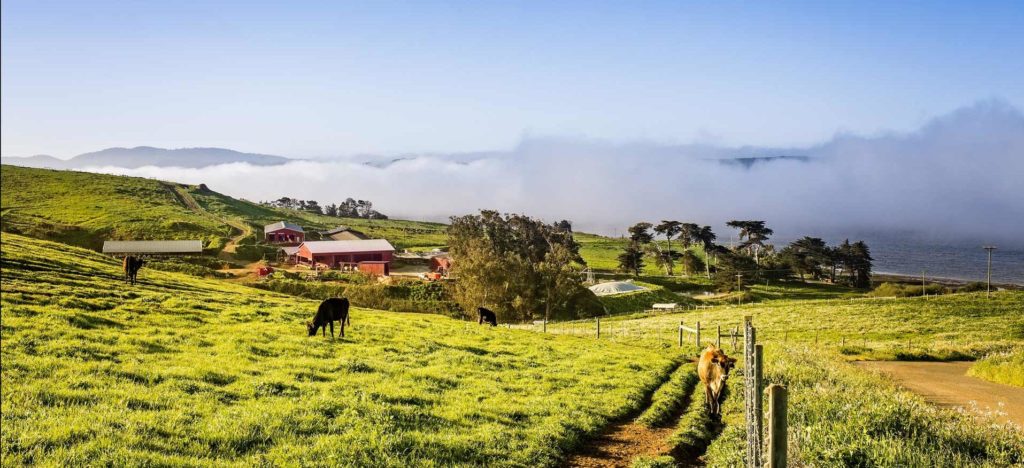

Straus Family Creamery is committed to creating a carbon-neutral dairy farming model on the Straus Dairy Farm. The Straus Dairy Farm is one of 13 dairy farms that supply certified organic milk to our Creamery. All of the supplying dairy farms are on the path to being carbon neutral by 2030.

Founder Albert Straus and seaweed-supplement maker Blue Ocean Barns demonstrated a dramatic climate change solution, reducing dairy cows’ enteric methane emissions an average of 52% and up to 90% by supplementing the cows’ diet with a specific red seaweed (Asparagopsis taxiformis) in the first U.S. commercial trial on a dairy farm in 2021.

In Spring 2022, the red seaweed received provisional regulatory approval, bringing Straus Dairy Farm one step closer to its carbon neutral goal. With Blue Ocean Barns solving the problem of growing the red seaweed at scale, Straus’ dairy is the first organic dairy farm committed to using this red seaweed when the certified organic feed becomes available. The red seaweed has the potential to reduce cows’ enteric methane emissions up to 95%. This is accomplished by feeding the dairy cows roughly one ounce of red seaweed as part of their regular 45-pound diet.

Carbon-neutral organic dairy farming model

Organic farming is the key to the carbon-neutral farming success. See how all the elements work together to help achieve the sustainability goals in our organic dairy farming model.

Organic Agriculture

Organic practices are the foundation of the Straus Dairy Farm's model for carbon-neutral dairy farming. Organic, pasture-based farming is better for the climate and provides environmental co-benefits such as enhanced water quality and biodiversity.

Methane Biodigesters & Renewable Energy

The biodigester on the Straus Dairy Farm takes in manure from the barns and captures the methane biogas emanating from that waste to generate electricity.

Seaweed Supplements

Enteric methane emissions (aka cow burps) are a major source of greenhouse gas emissions. Cow burps contribute about 2 billion tons of CO2 equivalent per year, more than 4 percent of all greenhouse gas emissions globally. During the 2021 Straus Dairy Farm and Blue Ocean Barns commercial trial, the red seaweed, the largest and longest yet conducted with seaweed and dairy cows, proved to dramatically reduce the cows' enteric methane emissions.

Regenerative Carbon Farming Practices

Carbon farming is a set of regenerative land management practices that build healthy soil and sequester atmospheric carbon. Albert Straus was the first dairy farmer in California to adopt a science-based Carbon Farm Plan (CFP) in 2013.

Electric Farm Equipment

The Straus Dairy Farm aims to eliminate fossil fuel emissions by converting all farm equipment to electric. The biodigester currently provides enough renewable electricity to charge Albert Straus' electric car, a full-scale electric truck, and other farm vehicles.

WORKING TOGETHER FOR SUSTAINABLE AGRICULTURE

Straus Family Creamery currently buys certified organic, non-GMO milk from 12 certified organic family farms in Marin and Sonoma counties. Together, we ensure an adequate supply of certified organic, dairy products of exceptional quality.

The combination of rich soil, one of the nation’s most diverse grassland systems, and a mild coastal climate create the ideal setting for organic dairy farming. Land stewardship and sustainable farming are deeply rooted principles in certified organic farming practices.

Environmental Leadership

Sustainable Manufacturing

Innovative practices to reduce waste and use renewable energy are the primary focus of our company’s sustainable business strategy. These innovations are consistent with Straus Family Creamery’s history of doing business right.

Read our Sustainability Reports.